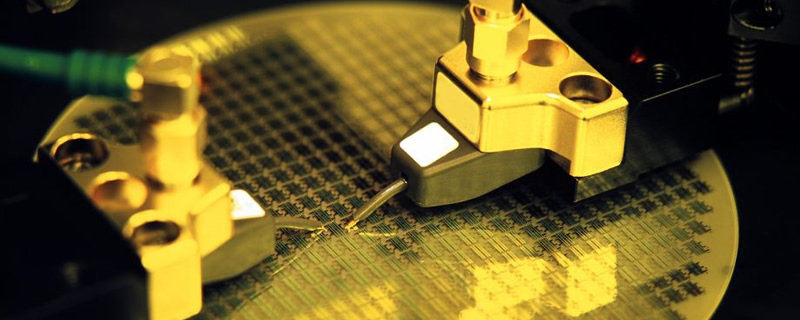

TSMC cleared to construct 3nm chip factory in Southern Taiwan

TSMC cleared to construct 3nm chip factory in Southern Taiwan

The new factory is expected to cost $19.5 billion to construct, with the facility itself relying on 20% renewable energy and 50% recycled water, factors which allowed TSMC to pass the facility’s environmental protection assessment. Â

Â

With every major lithography node shift, transistors become more densely packed and often becomes more energy efficient, allowing processors to become more complex and powerful. This makes process node shrinks a vital part of the PC industry, as these nodes are relied upon to deliver power and performance improvements.Â

At the time of writing, there are only three foundries that offer leading-edge lithography technology, TSMC, Samsung and Intel, with Global Foundries recently dropping out of the race. Creating each new lithography node is an expensive process and has become more difficult with each generation, though for now, TSMC seems content that they can continue pushing forward, at least until 3nm.Â

You can join the discussion on TSMC’s plans to construct a new 3nm foundry on the OC3D Forums. Â