OCZ Gladiator MAX CPU Cooler

Packaging & Appearance

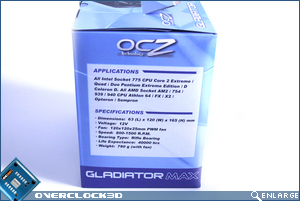

Looking very similar to the Vendettas packaging, the Gladiator Max is distinguished by the units title situated at the bottom of the box. To the rear of the box we find a perspective picture of the cooler showing it’s vertex fins and HDT technology. Key features adorn one side of the box with the applications and specifications on the opposite side.

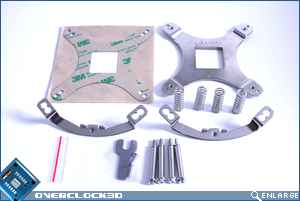

Opening the box up we find a well packed Styrofoam package containing both the cooler and accessories. The accessories themselves are nothing too remarkable with the AMD type pressure clip just sitting on the mid plate of the cooler and the push pin Intel fitment requiring two screws to attach to the cooler itself. Four rubber anti vibration mounting posts are also included which are a great commodity for those who desire silence. This are pulled through the fan holes and then slide in between the fins on the cooler which, while fiddly to fit are very secure, perhaps more so than some of the metal type clips used on the Gladiators competitors. With a small packet of paste also included everything is here to get you going. That is of course except a kit for skt 1366 fitment.

Available separately is the Skt1366 kit which contains a semi/permanent backplate for both Skt775 and skt1366. The difference with the skt1366 kit and skt775 (apart from the size of course) is the way that the kit attaches the cooler to the motherboard. Rather than use a push-pin setup the skt1366 kit utilises a much more professional spring/screw kit allowing for a better mount. Not only this but the included backplate will also allow for a greater application of pressure ensuring a solid but more importantly, even mount.

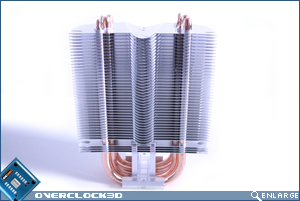

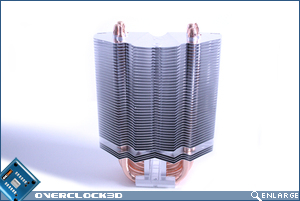

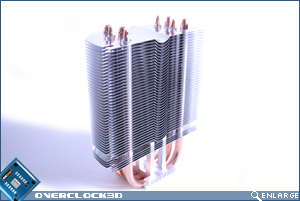

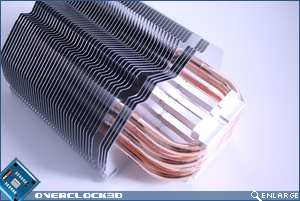

The cooler itself is similar to many other coolers on the market today. In that the heatpipes are threaded through a fin array. Perhaps the most individual feature of the Gladiator is the way the fins are arranged. Rather than having a flat appearance, the fins on the Gladiator are shaped to allow lower airflow resistance while directing the passing air towards the headpipes themselves which in turn should aid the dissipation of heat.

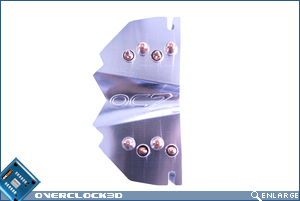

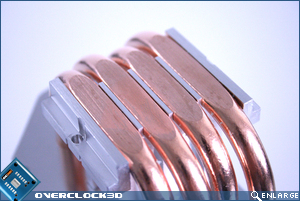

Using the HDT technology we covered earlier, the four heatpipes are slightly larger than the 6mm used in other heatsinks which in theory at least, should allow even greater heat conduction. Eradicating the dodgy soldering of base plates, H.D.T technology is rapidly becoming the most efficient process of wicking away heat from the CPU IHS. There is however a drawback to H.D.T in that more paste is used to fill in those inevitable gaps in the coolers base. Also worthy of note are the four pegs which protrude from the Aluminium base to wick as much heat as possible from the base of the cooler.

Â

Â

Â

Let’s take a look at our test setup and see how we got on fitting the Gladiator Max with the Skt1366 kit to our test bed…