The Truth about CPU Soldering

The Truth about CPU Soldering

Â

Ever since the release of Intel’s Ivy Bridge CPUs the process of delidding your CPU has be growing and growing in popularity, so much so that now there are even dedicated products for delidding your Intel CPUs and 3D models so that you can print a similar product yourself.

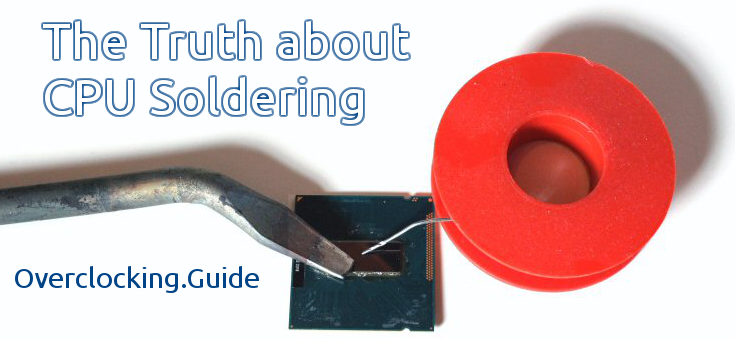

Over the past number of months the world class overclocker der8auer has been researching the process of soldering a CPU die to its IHS (Integrated Heat Spreader), and has recently posted his findings on his own website. In his article he writes about the benefits of Intel using their own thermal compound on their CPUs and how difficult it is to solder the CPU and the IHS together by soldering his own Skylake CPU.Â

Â

Soldered CPUs run much cooler than their cheaper thermal compound based counterparts for one simple reason, because it has a much higher thermal conductivity. For example the thermal conductivity of Indium (81.2W/mK), the solder used for soldering CPUs, is much higher than any common thermal compound, which has a  thermal conductivity which is typically between 5-10W/mK.

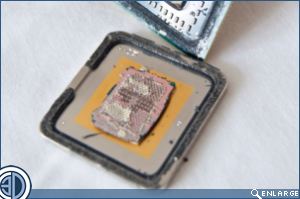

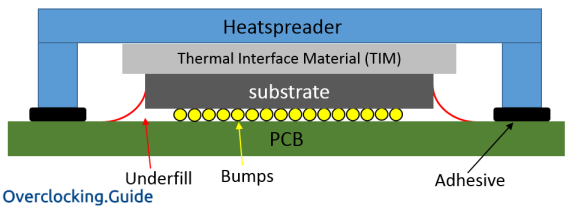

A lot of people say that Intel has done away with soldering their mainstream CPUs to the IHS solely because of cost, but that is only part of the reason, as the process of soldering a CPU die to the IHS is not only more expensive than than using some of Intel’s own thermal compound but is also several orders of magnitude more complex, not to mention the fact that it will use a lot of rare earth metals such as Gold, Nickel, Titanium and Vanadium and is not using ordinary Tin based solder but Indium based solder. Â Â

The Nickel coated copper IHS cannot be soldered directly to the silicon of your CPU, as it will damage the silicon CPU die, so before it can be soldered several layers of metal are needed to go between the heatspreader and Solder as well as between the solder and the silicon, making this process not just time consuming and expensive, but much more complex than adding a drop of Intel’s own thermal compound, despite the thermal disadvantages.Â

Intel do still solder the CPUs of more complex, hotter running Xeon and E-series CPUs (X99 etc) CPUs, but this is because these CPUs are hot enough running to require soldering and justifies the expense by being a much more premium/ high performance product.Â

Images from overclocking.guide

Â

With current generation mainstream CPUs from Intel being so power efficient and and cool running when compared to previous generations that the need for soldering CPU dies to the IHS had declined to the point that Intel now deems it as unnecessary and while this is very disappointing for us high end overclockers, it is hard for us to truly argue against the business sense of it all. Â

Intel has greatly improved the thermal compound that they use in their mainstream chips since Haswell, to a point where now we can use much higher voltages and clock speeds without hitting thermal limitations with Skylake. Hopefully Intel will continue to improve in this area, as better thermals usually means better overclocking, or at the very least that we can make our fans that little bit quieter.

I urge any of you that wish to know more about the process of soldering a CPU to please have a look at der8auer’s full article over on overclocking.guide, as it goes much deeper into the science and even looks into der8auer’s attempts to solder a Skylake CPU himself.

Â

You can join the discussion on the truth behind CPU Soldering on the OC3D Forums.Â

Â

Why do Intel use thermal paste on their consumer CPUs? Let’s find out. https://t.co/KtslNsnSy8 pic.twitter.com/xPIuwZ5UhI

— OC3D (@OC3D) November 25, 2015