IBM Unveils Super Conductive TIM

News Posted 23/03/07

Author: PV5150

Source: VR-Zone

According to our source, IBM researchers have unveiled details of a new technique to significantly increase capabilities to cool computer chips.

| The technique, developed by a team of scientists at the IBM Zurich Research Laboratory in cooperation with Momentive Performance Materials, formerly GE Advanced Materials, overcomes a barrier in chip cooling by improving the application of the “glue” that binds chips to their cooling systems. The new technology could allow faster computer chips to be cooled more efficiently. |

Currently, conventional Thermal Interface Material (T.I.M), has seen the inclusion of minute traces of metals or ceramic particles to assist with heat transfer between the CPU and heatsink. The purpose of the particles, is to create ‘heat evacuation bridges’; but yet the real problem lies within the glue that binds it all together.

| However, even highly particle-filled pastes are still inefficient, consuming up to 40 percent of the overall thermal budget, i.e. the cooling capacity available to draw heat away from the chip. |

IBM researchers now unveiled the reason and presented a novel technique to solve this problem:

| …By observing how the glue spreads when a chip is attached to its cooling element, scientists noticed that a cross formed in the paste as large numbers of particles were piling up, inhibiting the layers of glue from spreading out. The scientists were able to trace the cause of this back to the flow behavior of the paste, which simply follows the path of least resistance. Along the diagonals, the particles are pulled in opposite directions and, as a result, they remain where they are. As the squeezing process continues, however, they begin to pile up, forming what scientists call the “magic cross”.

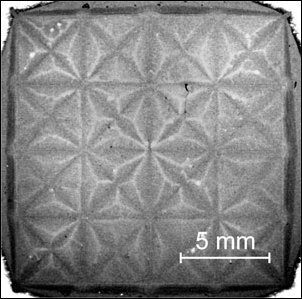

To overcome this problem, the team designed a special layout of micrometer-sized channels — or trenches — in a tree-like branched structure consisting of larger and smaller channels. This structure functions like an irrigation system for the paste at exactly those spots where the particles would pile up. This allows the particles to spread more homogeneously and reduces the thickness of the resulting paste gap. The results obtained are impressive: The paste thickness was reduced by a factor of 3, and the pressure needed to squeeze the paste to the same bondline thickness was reduced to a similar extent. These lower assembly pressures ensure that the delicate components and interconnects below the chip are not damaged as the chip package is created. The channels also allow pastes with higher fill factors and higher bulk thermal conductivity to be squeezed into thinner gaps, thereby reducing the thermal resistance of the paste interface considerably by more than a factor of 3. The new technology allows air-cooling systems to remove more heat and helps to improve the overall energy efficiency of computers. |

If you are interested in finding out more about IBM’s breakthrough in TIM technology, you may find it in a work entitled “Hierarchical Nested Surface Channels for Reduced Particle Stacking and Low-Resistance Thermal Interfaces” by R. J. Linderman, T. Brunschwiler, U. Kloter, H. Toy, B. Michel and will be published in Proc. 23rd IEEE Semi-Therm Symp. 2007.

(The pattern arising from the hierarchical channel design of the interface that controls and optimizes the spread of the paste.)